Page 1 of 2

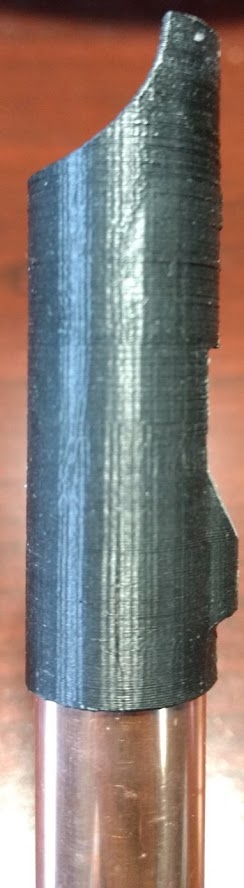

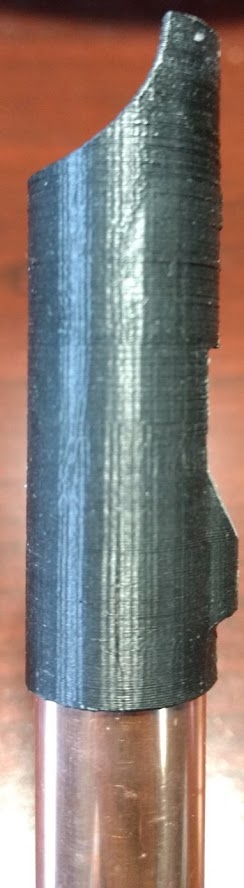

DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 3:44 pm

by VioPhilist

I recently finished a DIY copper pipe high D pennywhistle (pictures and recordings below) and wanted to talk about it (not a "for sale" post). The pipe is standard 5/8" copper pipe. I followed this tutorial

https://www.copper.org/consumers/copper ... istle.html. And used this amazing tool for calculating hole diameters

https://www.music.bracker.uk/Music/Whis ... lator.html. It is the first whistle I have ever made. I didn't have a drill press, so please forgive the very irregular holes! I noticed that the majority of the tutorial and hence the work goes into crafting the mouthpiece. I had some CAD experience from engineering school, as well as access to 3D printers, so I decided to design and print my own plastic mouthpiece. This saved a lot of time and effort, however, there of course are some inherrant flaws.

Whistle pros: I like the feel of copper and the way it patinas over time, the larger 5/8" diameter is also nice since I have large hands. The whistle is fairly loud. Louder than my Oak and Freeman Bluebird. And tone is pleasant to the ears. It is also decently in tune, though even with my tuneable mouthpiece I dont think it could play well with others.

Whistle cons:

Even after filing the fipple and the windway the whistle is too "breathy". I dont mind it being breathier than my Oak, but I'd like to dial it back a bit. It also requires too much air which makes the second octave very difficult (particularly anything above high G), the PLA mouthpiece is fragile and a seam between the print layers is tarting to open.

So, the problems lie with the mouthpiece. I used a makerbot replicator 2 with PLA filament. Admittedly, not the greatest printer or material. I believe that the mouthpice breathiness would be reduced if I could have it professionally printed so that it comes out very smooth. Secondly, I releaize that the design isn't perfect. The high breath requirement may require me to make the windway smaller.

So these are my questions to all you whistlers/whistle makers/experienced 3D printers: Do yall know of a good 3D printing service where I could order a high quality print of my mouthpiece and have it shipped to me? What material would be economical, smooth, hard, and not toxic for whistle mouthpiece? Resin, ABS(expesnisve)? Do you see any tweaks I could make in the design that might fix some of my issues?

Thanks!

Recordings (I'm still a beginner)

Loch Lomond

https://soundcloud.com/phileejo/loch-lo ... nnywhistle

Drunken Sailor

https://soundcloud.com/phileejo/drunken ... nnywhistle

Compared to my Oak D whistle

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 4:53 pm

by pancelticpiper

I'm no whistle maker, but to me the source of the breathiness and lack of air-efficiency seems obvious.

Usually if the floor of the windway is flat, so too is the roof (my little diagrams are turned sideways)

||

Or if the roof of the windway is curved, so too is the floor:

((

But you have a flat floor and a curved roof:

(|

which means that a considerable portion of the air doesn't hit the blade.

If it's a curved windway the blade curves to match, if it's a flat windway the blade is flat to match.

Efficiency comes from having as much of the air as possible strike the blade.

Here are two flat windways and one curved. In each case the blade matches up with the windway.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 5:08 pm

by TxWhistler

Congrats on your first try at whistle making and that you got it to make sound. Nice sound. Now the fun starts with you tweaking your design so that it makes very good or great sound!

You've done what I've wanted to do but I've not had access to a CAD or 3D printer. I was contemplating trying my hand at making a PVC whistle but so far haven't gotten started on the project.

So again congrats!!!

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 5:19 pm

by TxWhistler

pancelticpiper wrote:I'm no whistle maker, but to me the source of the breathiness and lack of air-efficiency seems obvious.

Usually if the floor of the windway is flat, so too is the roof (my little diagrams are turned sideways)

But you have a flat floor and a curved roof:

(|

which means that a considerable portion of the air doesn't hit the blade.

If it's a curved windway the blade curves to match, if it's a flat windway the blade is flat to match.

Efficiency comes from having as much of the air as possible strike the blade.

Richard, I'm definitely not a whistle maker either and just a rank novice at whistling, but here is something that I noticed about the Tilbury's whistles that I have. I'll post a picture later. I've got three of his whistles (C, Bb and low G). Each of them has a flat blade and the windway has a flat bottom and a curved top. His whistles have a pure sound and very little breathiness. I'm not sure how he achieves that but he does.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 5:45 pm

by TxWhistler

Here is what I was referring to:

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 7:59 pm

by Tommy

TxWhistler wrote:

Each of them has a flat blade and the windway has a flat bottom and a curved top. His whistles have a pure sound and very little breathiness. I'm not sure how he achieves that but he does.[/quote]

The windway exit is smaller than the blow in end. makes an efficient air steam against the blade.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 8:08 pm

by TxWhistler

Tommy wrote:TxWhistler wrote:

Each of them has a flat blade and the windway has a flat bottom and a curved top. His whistles have a pure sound and very little breathiness. I'm not sure how he achieves that but he does.

The windway exit is smaller than the blow in end. makes an efficient air steam against the blade.

Thanks for the info. I understand what's happening now.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 9:26 pm

by VioPhilist

Thank you pancelticpiper for the observation. That does make sense. Also, thank you txwhistler for the encouraging words! It is an exciting process. And those Tilburys are really unique! And thank you Tommy for shedding light on the unique design of the Tilbury whistles

I will modify the design by adding material to square off the windway. This shouldn't be difficult at all. Still need to choose a 3D printing service and material.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sat Aug 15, 2020 11:56 pm

by trill

VioPhilist,

Congratulations on getting sound !

My first few attempts were white noise generators.

Yes, the mouthpiece governs the voice. Not only that, it is a picky-picky-picky master. Any (and I mean *ANY*) change to the mouthpiece matters. One stroke of the file, and you have a new voice.

Here is a 3D prototyping company:

https://www.protolabs.com/

They offer online quotes. Huge base of materials.

What CAD package do you use ? At work, my favorite was SolidWorks. For home, it used to be Sketchup (when it was free).

Good luck !

trill

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sun Aug 16, 2020 2:59 am

by Dan A.

The copper looks great; hopefully it'll sound just as good. I have some copper tubing just laying around, and it may work as a whistle body. Maybe I'll give it a go someday.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sun Aug 16, 2020 7:01 am

by pancelticpiper

Interesting, I've never seen or played a Tilbury.

But if having that extra space at the top of the windway, meaning that a portion of the air passes well above the blade and is unused in tone production, can't possibly make for a whistle as efficient/focused as one with parallel roof and floor.

The only whistles I've played with a flat floor and curved roof, unmodified Clarkes and Shaws, were very inefficient. It's why I modified my Clarke by pushing down the roof to get rid of that dead space, create a flat roof parallel with the floor, giving an efficient focused whistle.

Well you did say your whistle is breathy and takes a lot of air and I think that's why.

I do realise that efficiency issues are more mitigated the smaller a whistle gets, and magnified the bigger a whistle gets. So a High D or High C Shaw or Clarke can still be played, but when I tried playing a Low D Shaw so much air was going through it was practically unplayable. I'm always coming at whistle from the Low Whistle perspective, which is sort of irrelevant for High Whistle players I guess.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sun Aug 16, 2020 11:52 am

by vigaglum

TxWhistler wrote:Richard, I'm definitely not a whistle maker either and just a rank novice at whistling, but here is something that I noticed about the Tilbury's whistles that I have. I'll post a picture later. I've got three of his whistles (C, Bb and low G). Each of them has a flat blade and the windway has a flat bottom and a curved top. His whistles have a pure sound and very little breathiness. I'm not sure how he achieves that but he does.

My Mack Hoover whistles have the same thing. I have the high D and low G, they both have flat bottoms and arched tops on the windway, and they are also of the pure sound variety.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sun Aug 16, 2020 3:58 pm

by Tunborough

Filling in some of the curvature of the roof of the windway would help with air consumption. It might help with the breathiness, too, but I'd also suggest you look for roughness in the windway, especially at the exit, and check where the bottom of the blade is relative to the air stream. I'd aim to have the bottom of the blade slightly above (i.e., farther from the centre line of the whistle) the level of the floor of the windway. It isn't quite clear from the photos, but your blade might be at or below the floor of the windway. MadmanWithaWhistle just suggested a difference of 0.02", or 0.5 mm. Personally, I'd aim for a bit less that that.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Sun Aug 16, 2020 6:59 pm

by VioPhilist

Thanks Trill! I will check protolabs out.

Yeah, SolidWorks is my favorite. I used SW to develop this design. But my student license has since run out. I did use the free web version of Sketchup to square off the windway. The web version is extremely limited, but for that minor change it worked great.

Tunborough, thanks for the input. Frankly the printed part does not adequately reflect this, but in my design the blade is above the floor of the windway by about 0.01" or 0.25mm. So half of what you said MadmanWithaWhistle suggested. I could cut a bit more material from my design to raise the blade above the windway floor further. I suspect that due to the surface roughness and resolution error of the 3D printer I used that this small but important gap was not maintained.

Re: DIY Copper Pennywhistle with 3D Printed Mouthpiece

Posted: Mon Aug 17, 2020 4:41 pm

by MadmanWithaWhistle

Your airblade design will influence how far into the airstream the edge should be raised, among other factors. I use Fusion 360 to aid in designing my instruments; it has a free version with most of the functions for home users. Bracker's hole calculator worked great for my first airblade design, but hates my current design, so don't get discouraged if tuning is more involved than expected.