Some D flutes in "Electrical Conduit Orange"

These are made following Doug Tipple's guidelines on his website:

http://tippleflutes.com/making-a-simple-irish-flute/

Tried a circular and a squared-ellipse embouchure. They both sound very similar actually. The circular hole is slightly larger so that flute needed to be longer to be in tune.

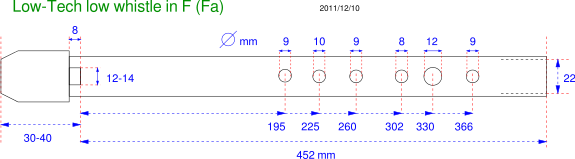

I also tried beveling the holes, as shown on Guido Gonzato's Low Tech Whistle guide (

http://www.ggwhistles.com/howto/).

The bevels feel very nice, and don't appear to alter the sound, however I fell that for fast tunes the non-beveled holes are preferable as you don't have to press as hard to fully close them.

The lip-plates are from a white PVC plumbing pipe with a slightly larger diameter and smaller wall-thickness. I leave the lip-plates unsanded and glossy which lets the lip stick very slightly to the plastic, whereas the orange pipe is sanded smooth for a matte finish, which feels nicer on the fingers. The surface is visually very like a peeled carrot!

Comparison with some other flutes to show the bore-size. First on the left is a Tipple D, third is a Dixon conical-bore, fourth is an M & E.

These pipes have a very nice size to them, slightly thinner than the pipes Doug Tipple uses but with really thick walls, which gives a nice tall chimney, particularly with a lip-plate. The color is a bit ridiculous, but I actually think it goes beyond ugly and has a certain industrial charm.

The sound is very similar to the Tipple (as you would expect, since I'm following his instructions) - I'll record a demo later.

Feadoggie wrote:I had a bit of a go at printing whistle heads a couple years back using a first gen Makerbot. My results were disappointing compared to what I can produce with a lathe and hand files.

Yes I also found the 3D printed whistle more of a gimmick than a real instrument. The extrusion printing just isn't reliable enough yet for consistent results so I think I'll stick with flutes for the time being.