Conical bore and tone holes

- Dan Mozell

- Posts: 64

- Joined: Wed Jan 31, 2007 10:54 am

- Please enter the next number in sequence: 1

- Contact:

Conical bore and tone holes

For all your makers and tweakers out there.

Anyone know how to calculate tone hole sizes and locations for CONICAL bores?

I thought I'd experiment with a poor man's version of a conical bore, modifying a pvc or cpvc tube with liquid plastic to create a pseudo conical bore.

Anyone know how to calculate tone hole sizes and locations for CONICAL bores?

I thought I'd experiment with a poor man's version of a conical bore, modifying a pvc or cpvc tube with liquid plastic to create a pseudo conical bore.

-

Gregrussell

- Posts: 76

- Joined: Fri Oct 03, 2008 3:49 pm

- Please enter the next number in sequence: 1

- Location: Newfoundland (alberta temp.)

- Contact:

Re: Conical bore and tone holes

Hi Dan,Dan Mozell wrote:For all your makers and tweakers out there.

Anyone know how to calculate tone hole sizes and locations for CONICAL bores?

I thought I'd experiment with a poor man's version of a conical bore, modifying a pvc or cpvc tube with liquid plastic to create a pseudo conical bore.

I use 1.618 as a division tool.....I first start by cutting the tube til the bell note is reached. then measure from the labium to the end of your tube. divide by 1.618 by 1.618 by 1.618....this will layout the nodes of your tube, layout your hole based on your nodes...you can see how the hole gets bigger closer to the node....Initially I choose my locations and reem the holes out until my hole size reaches the desired note....once I have the hole sizes I then choose a drill bit closest to the sizes uncovered by reeming. cover the holes you drilled with tape....turn your tube 180 degrees and drill new holes from the bottom up......and adjust new holes up or down to reach desired note....be prepared to scrap a tube or two...

I hope this helps...this is The way I do it......and it works, I don't trust magic formula's myself....It all comes down to customizing chaos for me

cheers,

Greg

Last edited by Gregrussell on Fri Jan 16, 2009 12:29 pm, edited 1 time in total.

- Feadoggie

- Posts: 3940

- Joined: Mon Feb 14, 2005 11:06 pm

- antispam: No

- Location: Stout's Valley, PA, USA

Re: Conical bore and tone holes

I hope this helps...this is The way I do it......and it works, I don't trust magic formula's myself....It all comes down to customizing chaos for me

Feadoggie

I've proven who I am so many times, the magnetic strips worn thin.

- Protean

- Posts: 380

- Joined: Mon Dec 08, 2008 3:51 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Amateur whistler for 14 years, amateur fiddler for 30 years. Haven't played either much in a while, looking to get back into it.

- Location: Atlanta, GA

Re: Conical bore and tone holes

Ye gods, how I want to make a whistle!

(Sorry, somewhat off topic, I know. But reading Greg's post, it just sounds like a lot of fun to me! )

)

(Sorry, somewhat off topic, I know. But reading Greg's post, it just sounds like a lot of fun to me!

-

highwood

- Posts: 562

- Joined: Thu Feb 07, 2008 3:30 pm

- antispam: No

- Please enter the next number in sequence: 12

- Location: Ohio

Re: Conical bore and tone holes

I know of no online sources for calculating holes in a conical instrument. Nederveen's book ('acoustical aspects of woodwind instrument') has the equations for both cylindrical and conical bores and much more, which include the first order approximations used by the spreadsheets that can be found online by, or based on Pete Kosel's work which are I believe also are used by the flutomat calculator.

So as not to mislead you the book does not give you a packaged solution - it is not a how to book!

A couple refinements to my cylindrical whistle design and I'm going to move on to trying a conical design, and diving into the math followed by almost certainly many prototypes.

Bill

So as not to mislead you the book does not give you a packaged solution - it is not a how to book!

A couple refinements to my cylindrical whistle design and I'm going to move on to trying a conical design, and diving into the math followed by almost certainly many prototypes.

Bill

“When a Cat adopts you there is nothing to be done about it except put up with it until the wind changes.” T.S. Elliot

- hans

- Posts: 2259

- Joined: Fri Nov 01, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I've been making whistles since 2010 in my tiny workshop at my home. I've been playing whistle since teenage times.

- Location: Moray Firth, Scotland

- Contact:

Re: Conical bore and tone holes

Greg - I wish I could understand your procedure, and the rational behind it. All I know is that dividing by 1.618 is the golden ratio, but i have no idea what that has to do with nodes and hole sizesGregrussell wrote:I use 1.618 as a division tool.....I first start by cutting the tube til the bell note is reached. then measure from the labium to the end of your tube. divide by 1.618 by 1.618 by 1.618....this will layout the nodes of your tube, layout your hole based on your nodes...you can see how the hole gets bigger closer to the node....Initially I choose my locations and reem the holes out until my hole size reaches the desired note....once I have the hole sizes I then choose a drill bit closest to the sizes uncovered by reeming. cover the holes you drilled with tape....turn your tube 180 degrees and drill new holes from the bottom up......and adjust new holes up or down to reach desired note....be prepared to scrap a tube or two...

~Hans

- hans

- Posts: 2259

- Joined: Fri Nov 01, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I've been making whistles since 2010 in my tiny workshop at my home. I've been playing whistle since teenage times.

- Location: Moray Firth, Scotland

- Contact:

Re: Conical bore and tone holes

Peter Hoekje's Exel spreadsheet gives the possibility to set the tube diameter for each tone hole location, so you can use it for a tapered bore.highwood wrote:I know of no online sources for calculating holes in a conical instrument. Nederveen's book ('acoustical aspects of woodwind instrument') has the equations for both cylindrical and conical bores and much more, which include the first order approximations used by the spreadsheets that can be found online by, or based on Pete Kosel's work which are I believe also are used by the flutomat calculator.

Pete Kosel's Flutomat javascript form page does not give that option and can be used only for cylindrical bores.

Both I find to be not very precise, but good for a first approximation.

Note that for a whistle design you need quite a different length correction for the whistle window than for the flute embouchure hole, i.e. the formula used for calculating the correction for the emb. hole needs adjustment.

~Hans

-

Gregrussell

- Posts: 76

- Joined: Fri Oct 03, 2008 3:49 pm

- Please enter the next number in sequence: 1

- Location: Newfoundland (alberta temp.)

- Contact:

Re: Conical bore and tone holes

Greg - I wish I could understand your procedure, and the rational behind it. All I know is that dividing by 1.618 is the golden ratio, but i have no idea what that has to do with nodes and hole sizes

~Hans[/quote]

Pluck a string on a guitar, and search for the harmonics by lightly touching the string without making it touch the frets and you will find pure Fibonacci and 1.618 relationships. A guitar string is not much different then the column of air in your whistle....Hence the fret board is also layed out this way....no wonder they call the number "golden"

~Hans[/quote]

Pluck a string on a guitar, and search for the harmonics by lightly touching the string without making it touch the frets and you will find pure Fibonacci and 1.618 relationships. A guitar string is not much different then the column of air in your whistle....Hence the fret board is also layed out this way....no wonder they call the number "golden"

-

Gregrussell

- Posts: 76

- Joined: Fri Oct 03, 2008 3:49 pm

- Please enter the next number in sequence: 1

- Location: Newfoundland (alberta temp.)

- Contact:

Re: Conical bore and tone holes

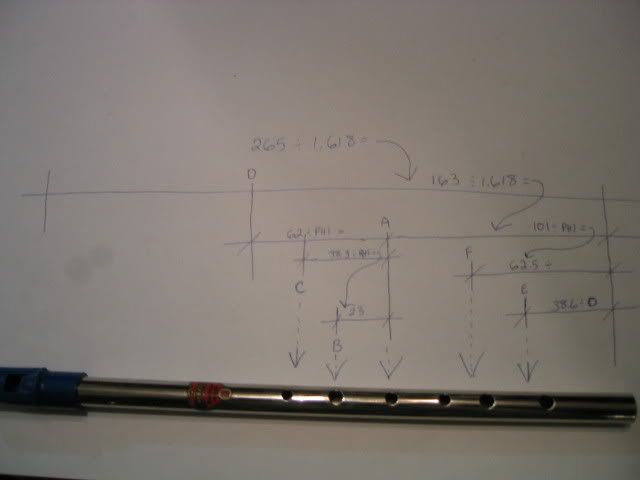

Hans, here is a picture of a generation d I missed the "G" ohwellhans wrote:Greg - I wish I could understand your procedure, and the rational behind it. All I know is that dividing by 1.618 is the golden ratio, but i have no idea what that has to do with nodes and hole sizesGregrussell wrote:I use 1.618 as a division tool.....I first start by cutting the tube til the bell note is reached. then measure from the labium to the end of your tube. divide by 1.618 by 1.618 by 1.618....this will layout the nodes of your tube, layout your hole based on your nodes...you can see how the hole gets bigger closer to the node....Initially I choose my locations and reem the holes out until my hole size reaches the desired note....once I have the hole sizes I then choose a drill bit closest to the sizes uncovered by reeming. cover the holes you drilled with tape....turn your tube 180 degrees and drill new holes from the bottom up......and adjust new holes up or down to reach desired note....be prepared to scrap a tube or two...

~Hans

- jiminos

- Posts: 627

- Joined: Mon Jan 07, 2008 12:09 am

- antispam: No

- Please enter the next number in sequence: 10

- Location: Pacific Coast of Washington State

Re: Conical bore and tone holes

thank you for the pic, greg. even without the G, it is pretty easy to understand. very cool. so... pardon my ignorance, but where did the 1.618 come from? when i make my flutes i use a much different way of calculating based on the 12 half tones from root to octave that make up the chromatic scale.

be well,

jim

be well,

jim

Jim

the truth is not lost.

do not search for it.

accept it.

the truth is not lost.

do not search for it.

accept it.

-

Gregrussell

- Posts: 76

- Joined: Fri Oct 03, 2008 3:49 pm

- Please enter the next number in sequence: 1

- Location: Newfoundland (alberta temp.)

- Contact:

Re: Conical bore and tone holes

Maybe the question is, "where did we come from" and "what are we doing here?"jiminos wrote:thank you for the pic, greg. even without the G, it is pretty easy to understand. very cool. so... pardon my ignorance, but where did the 1.618 come from? when i make my flutes i use a much different way of calculating based on the 12 half tones from root to octave that make up the chromatic scale.

be well,

jim

Check this out....http://goldennumber.net/music.htm

http://goldennumber.net/dna.htm

http://goldennumber.net/solarsys.htm

- jiminos

- Posts: 627

- Joined: Mon Jan 07, 2008 12:09 am

- antispam: No

- Please enter the next number in sequence: 10

- Location: Pacific Coast of Washington State

Re: Conical bore and tone holes

well, isn't that just cool as hell! absolutely fascinating! thank you very much for posting the links.

the geek/nerd in me is jumping up and down like a little child in a candy store.

be well,

jim

the geek/nerd in me is jumping up and down like a little child in a candy store.

be well,

jim

Jim

the truth is not lost.

do not search for it.

accept it.

the truth is not lost.

do not search for it.

accept it.

Re: Conical bore and tone holes

I am just having a short break from making one of these:

http://www.ehhs.cmich.edu/~dhavlena/low-d.htm

using one inch diameter thin wall aluminium allow tubing and a bit of broom handle.

Within an hour I had a tube sounding a low D!

Making the holes will be for tomorrow, but I think using a tapered reamer is the way to go for fine adjustment of sizes.

The guy who wrote that article says there is no difference in spacing between conical and cylindrical bore.

http://www.ehhs.cmich.edu/~dhavlena/low-d.htm

using one inch diameter thin wall aluminium allow tubing and a bit of broom handle.

Within an hour I had a tube sounding a low D!

Making the holes will be for tomorrow, but I think using a tapered reamer is the way to go for fine adjustment of sizes.

The guy who wrote that article says there is no difference in spacing between conical and cylindrical bore.

- hans

- Posts: 2259

- Joined: Fri Nov 01, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I've been making whistles since 2010 in my tiny workshop at my home. I've been playing whistle since teenage times.

- Location: Moray Firth, Scotland

- Contact:

Re: Conical bore and tone holes

I don't think this is the case.Gregrussell wrote:Pluck a string on a guitar, and search for the harmonics by lightly touching the string without making it touch the frets and you will find pure Fibonacci and 1.618 relationships. A guitar string is not much different then the column of air in your whistle....Hence the fret board is also layed out this way....no wonder they call the number "golden"

On a guitar the second harmonic is the fifth above the octave (first harmonic) and it occurs when dividing the string by three. Lightly touching the string one third way, so two thirds of the string remain, will sound the first harmonic (octave) of the fifth, i.e the same note which is fingerd a fifth above octave with a third of the string length. Two thirds is 0.666..., not 0.618 (golden proportion; 1/1.618=0.618).

Pressure nodes and anti-nodes in a flute or whistle are located similar, with the slight difference that the sounding air column is a little longer than the tube.

See flute acoustics. The pressure node in a flute for the first harmonic (octave) is located half way down the tube length, the pressure anti-nodes are located ca. one quarter and three quarters along the tube. The Golden Proportion has no bearing.

I have studied Fibonacci numbers and the Golden Proportion in nature, and find these to be fascinating aspects of naturally evolved efficient design, but when it comes to determine acoustically efficient location for flute tone holes I rather follow the maths of logarithmic divisions. To locate tone holes in places we organically evolved beings can reach comfortably with our fingers I then need to alter hole diameters (shift hole up: make it smaller; shift hole down: make it bigger) in a precise mathematical fashion which takes account of all the holes, or simply empirically by trial and error.

The resulting spread of holes has again nothing to do with the Golden Proportion. I aim to have somewhat equal distances between holes 1, 2 and 3, as between holes 4, 5 and 6. This is of course a big "somewhat", and usually a compromise between equal spacing and acoustically efficient spacing is best.

Great fun, all of this!

~Hans

-

Gregrussell

- Posts: 76

- Joined: Fri Oct 03, 2008 3:49 pm

- Please enter the next number in sequence: 1

- Location: Newfoundland (alberta temp.)

- Contact:

Re: Conical bore and tone holes

thanks hans....if it works it works, your much smarter then me....hans wrote:I don't think this is the case.Gregrussell wrote:Pluck a string on a guitar, and search for the harmonics by lightly touching the string without making it touch the frets and you will find pure Fibonacci and 1.618 relationships. A guitar string is not much different then the column of air in your whistle....Hence the fret board is also layed out this way....no wonder they call the number "golden"

On a guitar the second harmonic is the fifth above the octave (first harmonic) and it occurs when dividing the string by three. Lightly touching the string one third way, so two thirds of the string remain, will sound the first harmonic (octave) of the fifth, i.e the same note which is fingerd a fifth above octave with a third of the string length. Two thirds is 0.666..., not 0.618 (golden proportion; 1/1.618=0.618).

Pressure nodes and anti-nodes in a flute or whistle are located similar, with the slight difference that the sounding air column is a little longer than the tube.

See flute acoustics. The pressure node in a flute for the first harmonic (octave) is located half way down the tube length, the pressure anti-nodes are located ca. one quarter and three quarters along the tube. The Golden Proportion has no bearing.

I have studied Fibonacci numbers and the Golden Proportion in nature, and find these to be fascinating aspects of naturally evolved efficient design, but when it comes to determine acoustically efficient location for flute tone holes I rather follow the maths of logarithmic divisions. To locate tone holes in places we organically evolved beings can reach comfortably with our fingers I then need to alter hole diameters (shift hole up: make it smaller; shift hole down: make it bigger) in a precise mathematical fashion which takes account of all the holes, or simply empirically by trial and error.

The resulting spread of holes has again nothing to do with the Golden Proportion. I aim to have somewhat equal distances between holes 1, 2 and 3, as between holes 4, 5 and 6. This is of course a big "somewhat", and usually a compromise between equal spacing and acoustically efficient spacing is best.

Great fun, all of this!

~Hans

carry on,

Greg